耐磨带/环(图纸-尺寸)

耐磨带/环部分  工况条件 working condition

工况条件 working condition

Speed 速度 | Pressure range 压力范围 | Temperature 温度范围 | Medium 介质 | Available diameter range 可提供直径范围 |

15m/s | - | -55℃~+225℃ | Hydraulic liquid emulsion 液压油、乳化液、水 | Custom-tailor to requirements 按需求定制 |

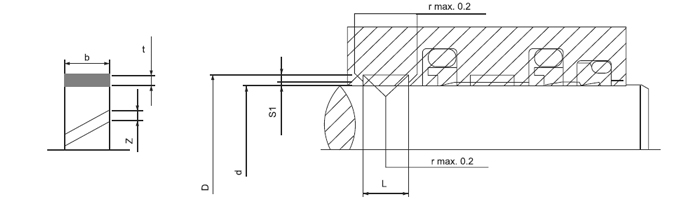

单向与双向作用液压与气动活塞用导向环

One-way and two way guide ring of hydraulic piston rod

D | d | L | S1 | t | b | z |

20-40 | D-4 | 4.2 | 0.5-1.5 | 2 | 4.0 | 1.0-2.0 |

25-80 | D-4 | 6.3 | 0.5-1.5 | 2 | 6.1 | 1.5-3.5 |

40-270 | D-4 | 8.1 | 0.5-1.5 | 2 | 7.9 | 2.0-5.0 |

40-320 | D-4 | 9.7 | 0.5-1.5 | 2 | 9.5 | 2.0-6.0 |

125-900 | D-4 | 15.0 | 0.5-1.5 | 2 | 14.8 | 4.0-8.0 |

200-900 | D-4 | 20.0 | 0.5-1.5 | 2 | 19.5 | 4.5-8.0 |

300-900 | D-4 | 25.0 | 0.5-1.5 | 2 | 24.5 | 6.0-8.0 |

300-999 | D-4 | 30.0 | 0.5-1.5 | 2 | 29.5 | 6.0-9.0 |

58单向与双向作用液压活塞用导向环

One-way and two way guide ring of hydraulic piston rod

D | d | L | S1 | t | b | z |

10-25 | D-3 | 3.2 | 0.4-1.0 | 1.5 | 3.0 | 1.0-1.5 |

20-40 | D-5 | 4.2 | 0.5-2.0 | 2.5 | 4.0 | 1.5-2.0 |

25-80 | D-5 | 6.3 | 0.5-2.0 | 2.5 | 6.1 | 1.5-3.5 |

40-270 | D-5 | 8.1 | 0.5-2.0 | 2.5 | 7.9 | 2.0-5.0 |

40-320 | D-5 | 9.7 | 0.5-2.0 | 2.5 | 9.5 | 2.0-6.0 |

125-900 | D-5 | 15.0 | 0.5-2.0 | 2.5 | 14.8 | 4.0-8.0 |

200-900 | D-5 | 20.0 | 0.5-2.0 | 2.5 | 19.5 | 4.5-8.0 |

300-900 | D-5 | 25.0 | 0.5-2.0 | 2.5 | 24.5 | 6.0-8.0 |

300-999 | D-5 | 30.0 | 0.5-2.0 | 2.5 | 29.5 | 6.0-9.0 |

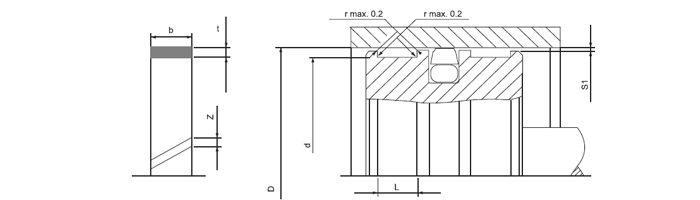

向与双向作用液压与气动活塞杆用导向环

One-way and two way guide ring of hydraulic and pneumatic piston rod

d | D | L | S1 | t | b | z |

15-35 | d+4 | 4.2 | 0.5-1.5 | 2 | 4.0 | 1.0-2.0 |

20-75 | d+4 | 6.3 | 0.5-1.5 | 2 | 6.1 | 1.5-3.5 |

30-250 | d+4 | 8.1 | 0.5-1.5 | 2 | 7.9 | 2.0-5.0 |

35-300 | d+4 | 9.7 | 0.5-1.5 | 2 | 9.5 | 2.0-6.0 |

120-900 | d+4 | 15.0 | 0.5-1.5 | 2 | 14.8 | 4.0-8.0 |

200-900 | d+4 | 20.0 | 0.5-1.5 | 2 | 19.5 | 4.5-8.0 |

300-900 | d+4 | 25.0 | 0.5-1.5 | 2 | 24.5 | 6.0-8.0 |

300-999 | d+4 | 30.0 | 0.5-1.5 | 2 | 29.5 | 6.0-9.0 |

单向与双向作用液压活塞杆用导向环

One-way and two way guide ring of hydraulic piston rod

d | D | L | S1 | t | b | z |

8-20 | d+3 | 3.2 | 0.4-1.0 | 1.5 | 3.0 | 1.0-1.5 |

15-35 | d+5 | 4.2 | 0.5-2.0 | 2.5 | 4.0 | 1.0-2.0 |

20-75 | d+5 | 6.3 | 0.5-2.0 | 2.5 | 6.1 | 1.5-3.5 |

30-250 | d+5 | 8.1 | 0.5-2.0 | 2.5 | 7.9 | 2.0-5.0 |

35-300 | d+5 | 9.7 | 0.5-2.0 | 2.5 | 9.5 | 2.0-6.0 |

120-900 | d+5 | 15.0 | 0.5-2.0 | 2.5 | 14.8 | 4.0-8.0 |

200-900 | d+5 | 20.0 | 0.5-2.0 | 2.5 | 19.5 | 4.5-8.0 |

300-900 | d+5 | 25.0 | 0.5-2.0 | 2.5 | 24.5 | 6.0-8.0 |

300-999 | d+5 | 30.0 | 0.5-2.0 | 2.5 | 29.5 | 6.0-9.0 |

相关资讯

制作思路 2013-04-16

制作思路 2013-04-16 巧磨垫圈 2013-04-27

巧磨垫圈 2013-04-27 聚氨酯油封6 2012-05-30

聚氨酯油封6 2012-05-30 O型橡胶密封圈在安全阀中的选用 2024-03-12

O型橡胶密封圈在安全阀中的选用 2024-03-12 接头 2013-05-14

接头 2013-05-14 四氟包覆O型圈选型时必须考虑的五大工况因素 2025-11-28

四氟包覆O型圈选型时必须考虑的五大工况因素 2025-11-28 橡胶O型密封圈的六个个主要优点,了解一下! 2024-09-10

橡胶O型密封圈的六个个主要优点,了解一下! 2024-09-10 不同材质橡胶O型圈的耐油性 2022-09-06

不同材质橡胶O型圈的耐油性 2022-09-06 O形圈的选用 2013-01-07

O形圈的选用 2013-01-07 橡胶O型圈的耐温范围 2021-12-22

橡胶O型圈的耐温范围 2021-12-22

上一篇:平垫圈(图纸-尺寸)

下一篇:PTFE档圈(图纸-尺寸)

返回